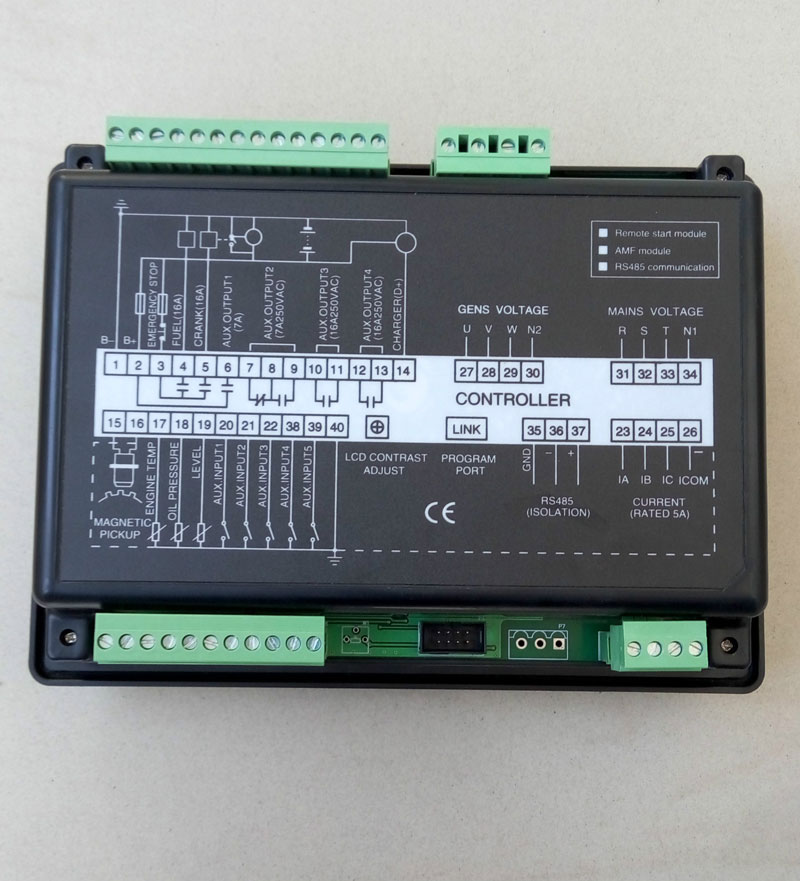

GM2011

Date:2017-02-22 Click:4447

The contents are intended for quick guidance and supplement supplement to the user who is using GM2000Ccontroller.

Please read the standard manual for more details.

GM2000C controller has four variants as shown

Note1:GM2011C/GM2012Cwith RS485 interface,GM2011/GM2012 without RS485 interface.

Note2: GM2011C/GM2012C is taken as an example to describe in this manual.

1 KEY FUNCTION DESCRIPTION

|

|

Stop/ Reset

|

Can stop generator under mode of Manual/Auto; Can reset shutdown alarm;press this key at least 3 seconds to test panel indicators are OK or not (lamp test); During stopping process, press this again can stop generator immediately. |

|

|

Start |

Start genset under Manual or Auto mode. |

|

|

Manual |

Pressing this key will setthe the module as Module mode. |

|

|

Auto |

Pressing this key will setthe the module as Auto mode. |

|

|

Running with load |

controller is under manual testing mode. Under this mode, genset will run with load automatic when gens are normal. (GM2011Cwithout). |

|

|

Set/ Confirm |

Enters into Set menu after pressing this, and can shift ursor to confirm. |

|

|

Page up/increase |

Screen scroll;Shift cursor and increase values. |

|

|

Page Down/Decrease |

Screen scroll;Shift cursor and decrease values. |

2 PARAMETER EDITING

|

After

controller powered on ,press![]() to enter the parameters setting menu item as

shown:

to enter the parameters setting menu item as

shown:

1) press![]() key to enter the menu interface after

controller started,choose 1. (See Fig1

key to enter the menu interface after

controller started,choose 1. (See Fig1

Fig1);

|

2)

press![]() key to enter parameter confinguration

password confirm interface(See Fig2);

key to enter parameter confinguration

password confirm interface(See Fig2);

When 1234 is input,part of the parameter can be set;when 0318 is input,all the Fig2

parameter can be set;

3)

press![]() or

or![]() key to increase or decrease values;press

key to increase or decrease values;press![]() key to shift bit and confirm setting;

key to shift bit and confirm setting;

4)

If password is correct,enter into parameter interface; press![]() or

or![]() key to choose parameter items;press

key to choose parameter items;press![]() key to

key to

Enter into current parameter setting memu;

5) If parameter within the range,the setting can be saved in internal FLASH of controller. If out of range,it can’t

be saved.

Note:Pressing![]() key at any time can exit the editor and

return to main menu.

key at any time can exit the editor and

return to main menu.